Description

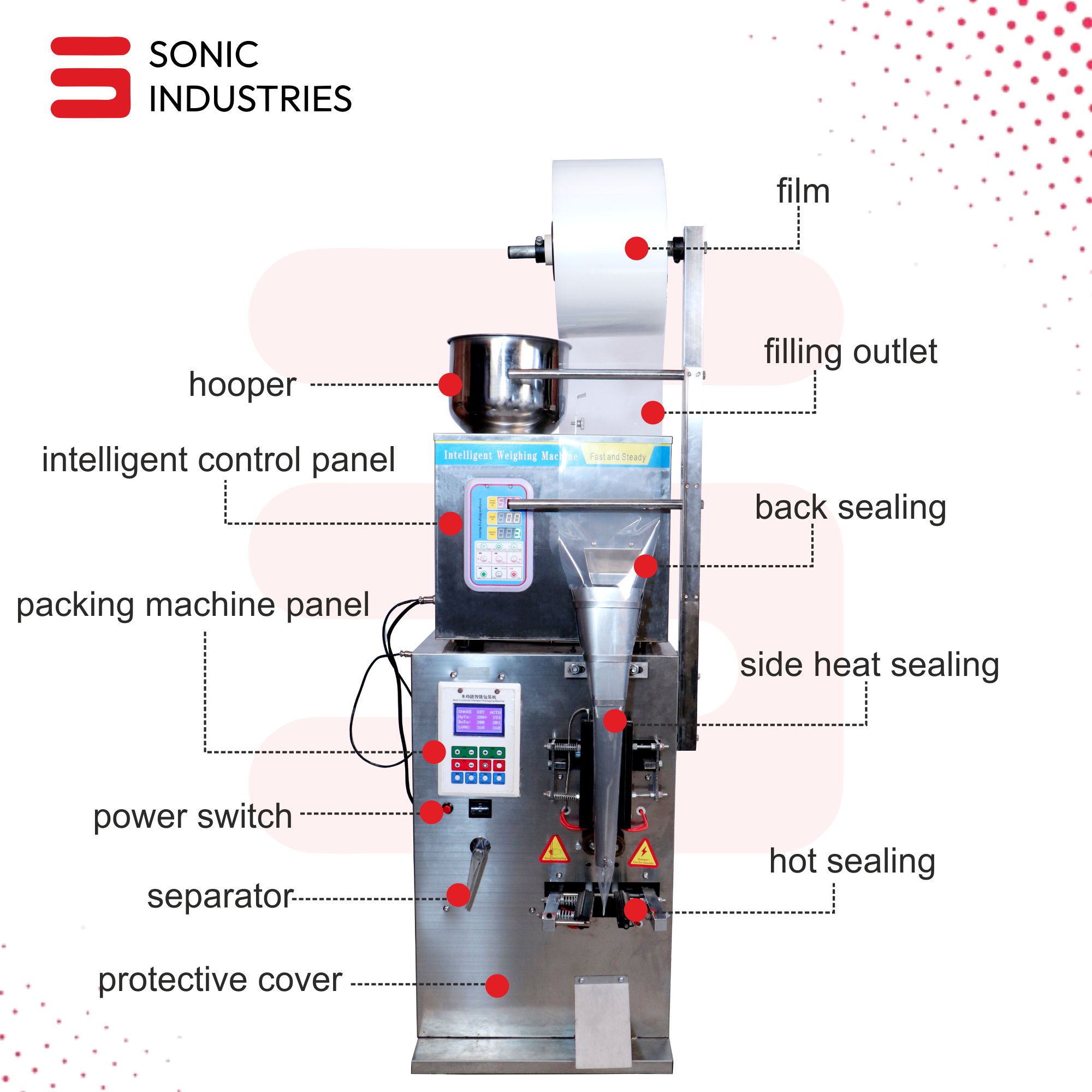

Sonic Industries FFS 1000 Single‑Head Filling Machine – High‑Capacity Form‑Fill‑Seal Solution for 50 g to 1 kg Pouches

Introduction

In modern manufacturing, packaging efficiency, precision, and reliability are non‑negotiable. Whether in the food industry, pharmaceutical manufacturing, or industrial sectors, businesses need packaging solutions that enhance productivity, maintain consistency, and improve product presentation.

The Sonic Industries FFS 1000 Single‑Head Filling Machine is a high‑capacity, fully automated form‑fill‑seal (FFS) system designed for granule and powder products. With a filling capacity of 50 g to 1 kg, this machine is ideal for medium‑to‑large production lines. Its 420 mm maximum roll width accommodates a wide range of pouch sizes, offering versatility for various packaging requirements.

This machine is perfect for manufacturers looking to scale their packaging operations while maintaining product integrity and brand consistency.

Key Features & Advantages

1. Wide Filling Range (50 g to 1 kg)

This machine handles small‑format retail pouches (50 g) as well as bulk packs (up to 1 kg). This flexibility makes it suitable for businesses with diverse product lines, including snacks, grains, spices, coffee, powders, and industrial products.

2. High‑Capacity Single‑Head Filling

Equipped with a precise volumetric or auger filler, the machine ensures consistent and accurate filling, reducing product giveaway and optimizing cost efficiency.

3. Large Roll Handling (Max 420 mm)

With a 420 mm maximum roll width, the FFS 1000 supports larger pouch formats and provides ample space for custom branding and product labeling, ensuring retail‑ready presentation.

4. Fully Automated Form‑Fill‑Seal Operation

The machine forms pouches from roll stock, fills them accurately, and seals them securely in one continuous process. This streamlined operation reduces manual labor, improves production speed, and ensures uniform output quality.

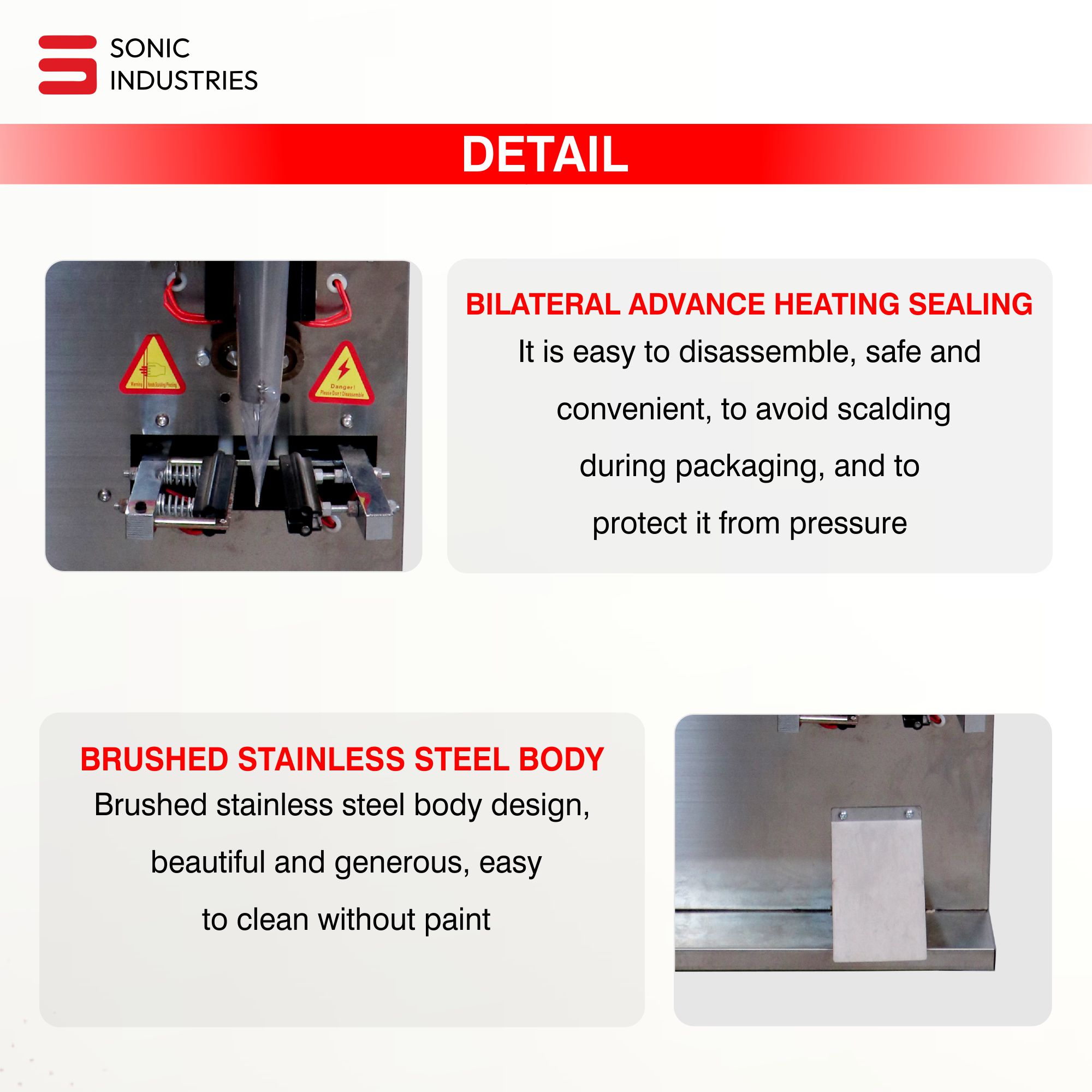

5. Reliable Heat‑Sealing Technology

The heat‑sealing mechanism delivers airtight, tamper‑proof seals that protect against moisture, contamination, and leakage, significantly enhancing product shelf life.

6. Hygienic & Durable Construction

Made from SS304 stainless steel, the machine complies with international hygiene standards, making it safe for food and pharmaceutical packaging while also being resistant to wear and corrosion.

7. User‑Friendly Interface

The machine features an intuitive HMI touchscreen control system, allowing operators to easily adjust settings for pouch dimensions, fill weights, and sealing parameters, ensuring a smooth and efficient operation.

8. Space‑Efficient Design

The FFS 1000 packs industrial‑grade performance into a compact footprint, making it a great fit for space‑constrained production facilities.

9. Low Maintenance & Cost‑Effectiveness

Designed for ease of cleaning and simple servicing, the machine ensures long‑term reliability with minimal downtime, offering an excellent return on investment.

Applications Across Industries

The FFS 1000 Single‑Head Filling Machine is a versatile solution for a wide range of industries:

-

Food & Beverage: Coffee, tea, spices, sugar, flour, rice, pulses, dry fruits, seeds, snacks, and powdered drink mixes.

-

Pharmaceutical & Nutraceutical: Herbal blends, medicinal powders, dietary supplements, vitamins.

-

Chemical & Industrial: Agrochemicals, fine granules, cleaning agents, and other dry industrial materials.

-

Pet Food & Animal Feed: Granulated and powdered pet food or animal feed supplements.

Its broad compatibility makes it an excellent choice for businesses with diverse packaging needs.

Benefits of the Sonic FFS 1000 Single‑Head Machine

-

Increased Efficiency: Automated pouch forming, filling, and sealing for fast and reliable packaging.

-

Flexibility: Handles multiple pouch sizes and weights for different product types.

-

Consistency: Accurate volumetric filling ensures precise product quantities in every pack.

-

Extended Shelf Life: Airtight seals protect products from environmental exposure.

-

Professional Packaging: Produces retail‑ready pouches with consistent quality and appearance.

-

Cost Savings: Reduced labor and optimized material usage lower overall production costs.

Technical Specifications

-

Model: Sonic Industries FFS 1000 Single‑Head Filling Machine

-

Filling Range: 50 g to 1 kg

-

Filling System: Single‑head volumetric/auger filler (customizable)

-

Film Roll Width: Max 420 mm

-

Sealing Type: Heat‑seal (temperature adjustable)

-

Pouch Type: Laminated/multi‑layer pouches

-

Material of Construction: Stainless Steel (SS304)

-

Power Requirement: 220 V / 50 Hz (Single‑Phase/Three‑Phase options)

-

Control Interface: Touchscreen HMI for easy operation

-

Safety Features: Emergency stop, overheat protection, secure sealing controls

-

Production Speed: Medium to high (depends on pouch size and product type)

Step‑by‑Step Working Process

-

Film Feeding: The machine feeds film from a roll (up to 420 mm width).

-

Pouch Formation: Film is shaped into pouches using a forming collar.

-

Product Filling: Granules or powders are filled into the pouch with high precision.

-

Heat Sealing: Pouches are sealed securely to maintain freshness and integrity.

-

Discharge: Finished pouches are discharged, ready for boxing, labeling, or secondary packaging.

Frequently Asked Questions (FAQs)

Q1: Can this machine handle different types of products?

Yes. It is designed for granules and powders, and can be customized for specific product needs.

Q2: Is it easy to change pouch sizes?

Absolutely. The touchscreen interface allows for quick adjustments in pouch dimensions and fill weights.

Q3: Does it support branded packaging films?

Yes. It is compatible with laminated and multi‑layer films, allowing for custom branding and high‑quality printing.

Q4: Can it be integrated with other packaging equipment?

Yes. It can be connected with labelers, conveyors, and secondary packaging systems.

Q5: How often does it require maintenance?

It requires basic preventive maintenance and regular cleaning for optimal performance and extended service life.

Reviews

There are no reviews yet.