Description

FFS 1000 1 kg/3 kg Two‑Head Filling Machine

Introduction

Two-Head Filling Machine (50g to 1kg) For businesses handling medium‑ to large‑format granule and powder packaging, speed and accuracy are the cornerstones of operational success. Industries like food, nutraceuticals, and chemicals require high‑capacity solutions that can keep up with large production demands while maintaining precision and product integrity.

The Sonic Industries FFS 1000 1 kg/3 kg Two‑Head Filling Machine has been designed to answer this exact need. With its dual‑head filling system, 50 g to 1 kg capacity, and large 420 mm roll handling, it is a powerhouse for high‑efficiency packaging. This model bridges the gap between speed and precision, making it a must‑have for high‑volume manufacturers aiming for productivity and consistency.

Key Features & Advantages

1. Dual‑Head High‑Speed Filling

The two‑head filling system significantly boosts production capacity, enabling two pouches to be filled simultaneously. This results in increased throughput without compromising accuracy.

2. Versatile Filling Range (50 g to 1 kg)

Whether you need small retail packs or larger consumer‑sized pouches, this machine accommodates 50 g to 1 kg formats, offering flexibility for different product lines.

3. Large Film Roll Handling (Max 420 mm)

The 420 mm roll width capacity supports large‑format pouches and branded multi‑layer films, ensuring professional‑grade packaging.

4. Precision Volumetric/Auger Filling

Equipped with high‑accuracy volumetric or auger fillers, this system delivers consistent product weights for every pouch, reducing product giveaway and wastage.

5. Automated Form‑Fill‑Seal Technology

From pouch forming to filling and sealing, the entire process is fully automated, reducing human error and improving production speed.

6. Reliable Heat Sealing

The heat‑seal mechanism ensures airtight, tamper‑proof pouches, preserving product freshness and quality over longer shelf lives.

7. Robust & Hygienic Construction

Built with SS304 stainless steel, this machine is durable, easy to clean, and compliant with food and pharma hygiene standards.

8. Intuitive HMI Controls

An easy‑to‑use touchscreen interface allows operators to adjust pouch size, fill weight, sealing parameters, and speed with minimal training.

9. Designed for Large‑Scale Operations

With its high‑speed, dual‑head design, the FFS 1000 1 kg/3 kg model is built for 24/7 heavy‑duty performance, making it ideal for industrial‑scale packaging needs.

Applications Across Industries

This two‑head FFS machine is suitable for a variety of applications:

-

Food & Beverage: Grains, pulses, sugar, coffee, tea, spices, dry fruits, and powdered drink mixes.

-

Pharmaceutical & Nutraceutical: Medicinal powders, herbal blends, and supplement granules.

-

Industrial & Chemical: Fertilizers, cleaning agents, and fine industrial granules.

-

Pet Food: Granules and powdered animal feed supplements.

Its flexible filling range makes it a perfect match for companies managing multiple SKUs with different packaging needs.

Benefits of the Sonic FFS 1000 1 kg/3 kg Two‑Head Filling Machine 50 g to 1 kg

-

Increased Throughput: Two filling heads ensure higher production rates.

-

Accuracy & Consistency: Precise volumetric dosing maintains consistent product weights.

-

Extended Shelf Life: Tamper‑proof heat sealing ensures freshness.

-

Flexibility: Handles a variety of pouch sizes and fill weights.

-

Cost‑Effective: Optimized film usage and reduced labor requirements save costs.

-

Professional Packaging: Produces retail‑ready, branded pouches with excellent finish.

Product Specifications

Two-Head Filling Machine (50g to 1kg)

-

Model: Sonic Industries FFS 1000 1 kg/3 kg Two‑Head Filling Machine

-

Filling Range: 50 g to 1 kg

-

Filling System: Dual‑head volumetric/auger filler

-

Film Roll Width: Max 420 mm

-

Sealing Type: Heat‑seal with temperature control

-

Pouch Type: Laminated/multi‑layer heat‑sealable pouches

-

Material of Construction: SS304 stainless steel

-

Control Interface: Touchscreen HMI

-

Power Requirement: 220 V / 50 Hz (Single/Three‑Phase)

-

Production Speed: High‑capacity output (varies with product/pouch size)

-

Safety Features: Emergency stop, overheat protection, interlocks

-

Applications: Food, pharma, chemical, and industrial powders and granules

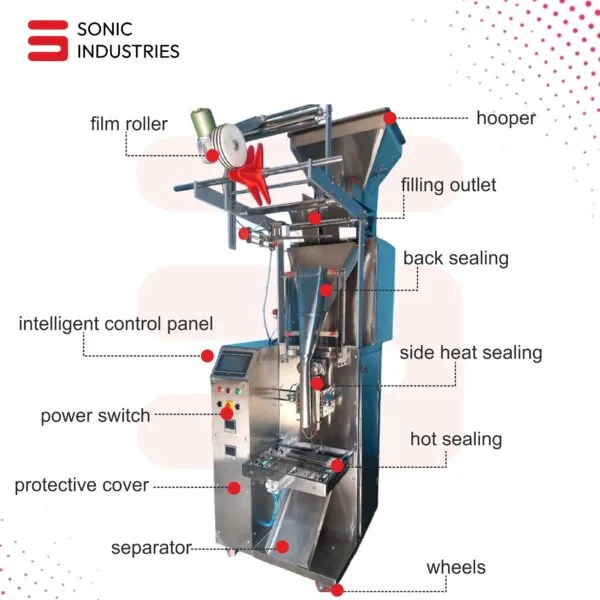

How It Works – Step by Step

-

Film Feeding: Film is unwound from a roll (up to 420 mm wide).

-

Pouch Forming: The film is shaped into pouches using a forming collar.

-

Dual Filling: Two filling heads simultaneously fill pouches with precise dosages.

-

Heat Sealing: Sealing jaws create airtight, tamper‑proof pouches.

-

Pouch Discharge: Sealed pouches are released for secondary packaging or shipping.

Frequently Asked Questions (FAQs)

Q1: Can this machine handle different types of granules?

Yes, it can handle a variety of free‑flowing and semi‑free‑flowing granules as well as powders.

Q2: Is it compatible with custom‑printed films?

Absolutely. It supports laminated and multi‑layer branded films for professional packaging.

Q3: How easy is it to change pouch sizes?

Very easy. The HMI control system allows quick adjustments for different pouch formats and fill weights.

Q4: Can it integrate into a full packaging line?

Yes. It can be combined with conveyors, labelers, and boxing systems for a complete packaging solution.

Q5: What maintenance is required?

Only routine cleaning and preventive maintenance are needed for smooth operation and long‑term reliability.

Reviews

There are no reviews yet.