Description

Pneumatic Liquid Filling Machine – 100ml to 1000ml

Semi-Automatic, Air-Driven Liquid Filling Solution for Medium-Volume Bottling Operations

Introduction

In today’s fast-moving manufacturing environment, efficiency, hygiene, and accuracy are the key to successful packaging. The Pneumatic Liquid Filling Machine 100ml to 1000ml from Sonic Industries is a semi-automatic solution designed to help businesses fill low to moderately viscous liquids in the 100ml to 1000ml range. Ideal for edible liquids, beverages, oils, chemicals, sanitizers, herbal extracts, and pharmaceutical syrups, this machine is the go-to solution for startups, MSMEs, and mid-level factories aiming to enhance production speed without compromising on precision.

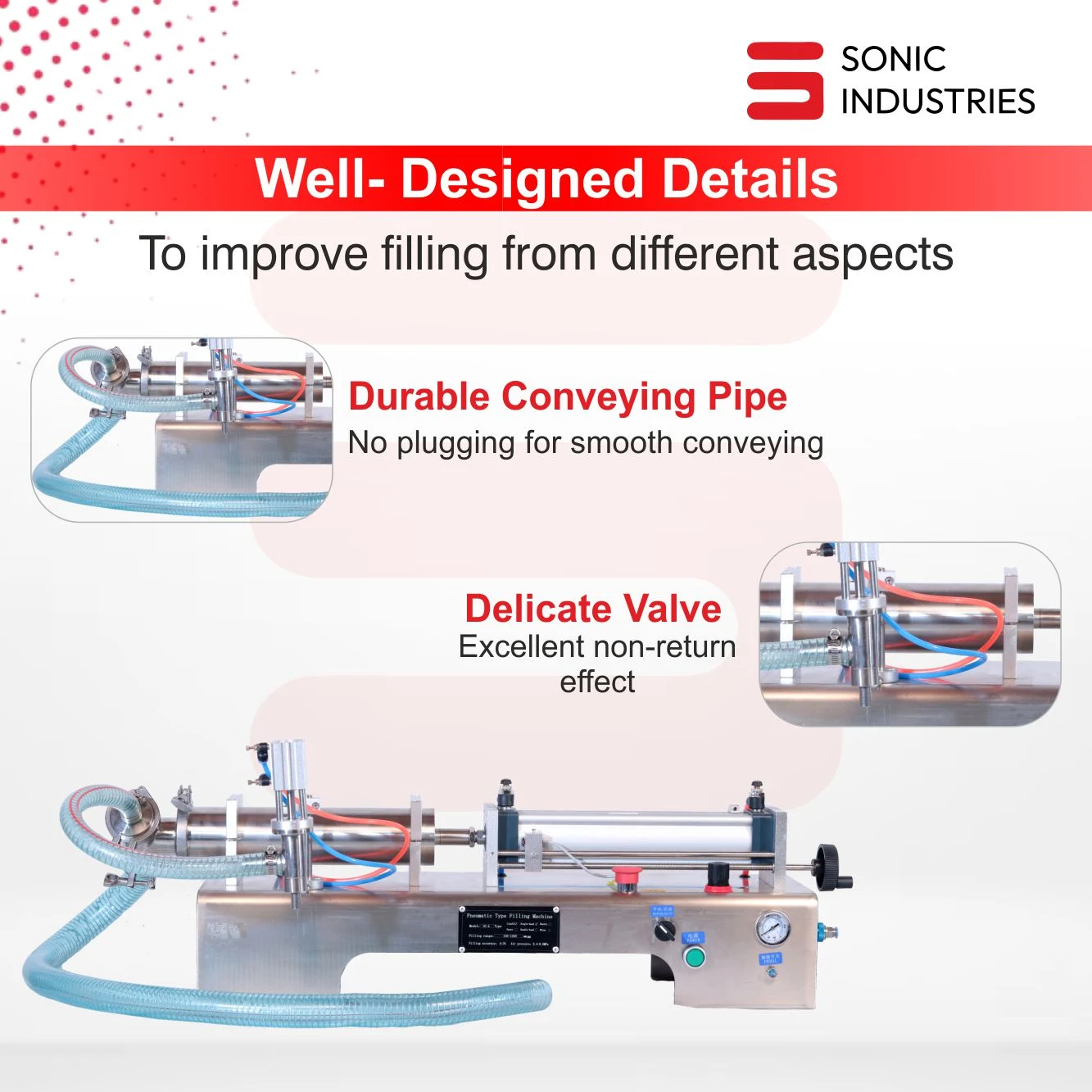

Powered by compressed air and built with SS304 food-grade stainless steel, this model offers excellent hygiene, durability, and ease of operation. Its anti-drip nozzle, adjustable piston stroke, and foot pedal activation make it a user-friendly choice for anyone looking to upgrade from manual filling to a controlled, semi-automated process.

Key Highlights Pneumatic Liquid Filling Machine 100ml to 1000ml

1. Adjustable Filling Volume (100ml–1000ml)

Designed for flexibility, this machine is capable of filling a wide range of container sizes. From small medicine bottles to large 1-litre juice packs, you can set the desired volume using a simple mechanical adjustment, ensuring consistent and accurate filling across every batch.

2. Pneumatic Power – No Electricity Needed

This model operates purely on compressed air. It is ideal for operations in hazardous environments, where electric machines pose a safety risk, or in rural or mobile setups where power supply is inconsistent. It also reduces your electricity costs and maintenance requirements.

3. 1% High Accuracy

Thanks to its piston-filling technology, this machine delivers a precise fill every time. The volume is controlled by the piston’s stroke length, enabling the machine to maintain high repeatability and uniformity, crucial for customer satisfaction and compliance.

4. Stainless Steel SS304 Body & Contact Parts

The machine’s frame and all liquid contact components are made from SS304 stainless steel, which is rustproof, corrosion-resistant, and compliant with food and pharma-grade standards. An upgrade to SS316 is available for corrosive chemicals or specialized applications.

5. Anti-Drip Nozzle

The stainless steel nozzle is equipped with an automatic shut-off mechanism that prevents any dripping after the fill, ensuring clean packaging and minimal product loss.

6. Simple Foot Pedal Control

The machine is triggered using a foot pedal, allowing operators to work hands-free while handling containers. This setup increases productivity and reduces fatigue, especially during long shifts.

7. Quick Disassembly for Cleaning

Tool-free design enables quick disassembly of the hopper, piston, and nozzle for thorough cleaning. The system is GMP-compliant, and suitable for factories with strict cleanliness requirements.

Technical Specifications

| Specification | Details |

|---|---|

| Model | Pneumatic Liquid Filler – 100ml to 1000ml |

| Filling Volume | 100ml – 1000ml (adjustable) |

| Filling Speed | 8 – 18 bottles per minute (product-dependent) |

| Filling Accuracy | ±1% |

| Drive Type | Pneumatic (Air-Driven) |

| Required Air Pressure | 0.4 – 0.6 MPa |

| Body Material | SS304 (SS316 optional) |

| Nozzle | Stainless Steel Anti-Drip |

| Control | Foot Pedal / Manual Trigger |

| Hopper Capacity | 25L / 40L (customized as per requirement) |

| Cleaning | Tool-Free Manual Cleaning |

| Machine Weight | 30 – 45 kg (model-dependent) |

| Power Requirement | None (air compressor only) |

Compatible Liquids

The Pneumatic Liquid Filling Machine – 100ml to 1000ml is ideal for filling non-viscous to semi-viscous products. Its versatility allows it to serve across multiple industries:

Food & Beverage

-

Water

-

Cold-pressed juices

-

Herbal drinks

-

Edible oils

-

Coconut water

-

Amla and aloe vera juices

Pharmaceuticals

-

Cough syrups

-

Tonics

-

Ayurvedic medicines

-

Digestive liquids

-

Homeopathic solutions

Cosmetics & Personal Care

-

Rose water

-

Hair oil

-

Face wash

-

Body lotions (light viscosity)

-

Floral waters

Chemicals & Cleaners

-

Liquid detergents

-

Sanitizers

-

Disinfectants

-

Phenyl

-

Liquid fertilizers

Industry Applications

This machine is widely used in:

| Industry | Use Case |

|---|---|

| FMCG | Bottling edible oils, herbal drinks |

| Pharmaceuticals | Syrups, tonics, and elixirs |

| Cosmetics | Hair oils, liquid skincare products |

| Chemical Industry | Liquid detergents, cleaning liquids |

| Contract Packaging | Versatile filling for multiple clients |

| Startups | Affordable filling machine for scaling business |

Top 10 Benefits for Your Business

1. Multi-Size Compatibility

Adjustable filling range makes it suitable for a variety of bottle sizes, offering operational flexibility.

2. Clean & Controlled Filling

The anti-drip nozzle prevents wastage, mess, and contamination — helping maintain packaging quality.

3. Hygienic and Food-Grade

Made with SS304, the machine is built to ensure hygiene in food, cosmetics, and pharmaceutical applications.

4. Electricity-Free Operation

No motor, no electric connection — just a reliable air compressor and the machine is ready to run.

5. Compact & Portable

Its compact size allows it to be used on workbenches or small production tables. An optional trolley base makes it mobile.

6. Easy Maintenance

With fewer moving parts, the machine is extremely easy to maintain and operate with minimal downtime.

7. High Accuracy & Consistency

Perfect for maintaining uniform bottle fill levels, enhancing your product’s presentation and brand credibility.

8. Quick Cleaning

Disassemble, rinse, and reassemble in minutes — making it ideal for businesses running multiple product lines.

9. Operator-Friendly

Requires minimal training. A single operator can comfortably manage the filling process.

10. Long-Term Value

Built to last with premium components, delivering a strong return on investment over years of use.

Optional Features & Upgrades

| Upgrade | Benefit |

|---|---|

| SS316 Contact Parts | For pharma or acidic chemical handling |

| Double Nozzle | Double your output with two simultaneous fills |

| Heated Hopper | Keeps oils and other liquids at flowable temp |

| Digital Counter | Tracks filled bottles in real time |

| Trolley with Castor Wheels | Mobile setup for larger production floors |

| Vacuum Anti-Foaming Kit | Essential for foaming liquids like sanitizers |

Cleaning & Maintenance Guide

Step-by-Step Cleaning Instructions:

-

Disconnect the air line.

-

Release clamps and remove hopper.

-

Detach nozzle and piston by hand (no tools needed).

-

Rinse all parts with water or food-grade sanitizer.

-

Dry and reassemble in under 10 minutes.

Recommended Cleaning Frequency:

-

After every production shift

-

After product type changes

-

End of the day for hygiene compliance

Reviews

There are no reviews yet.