Description

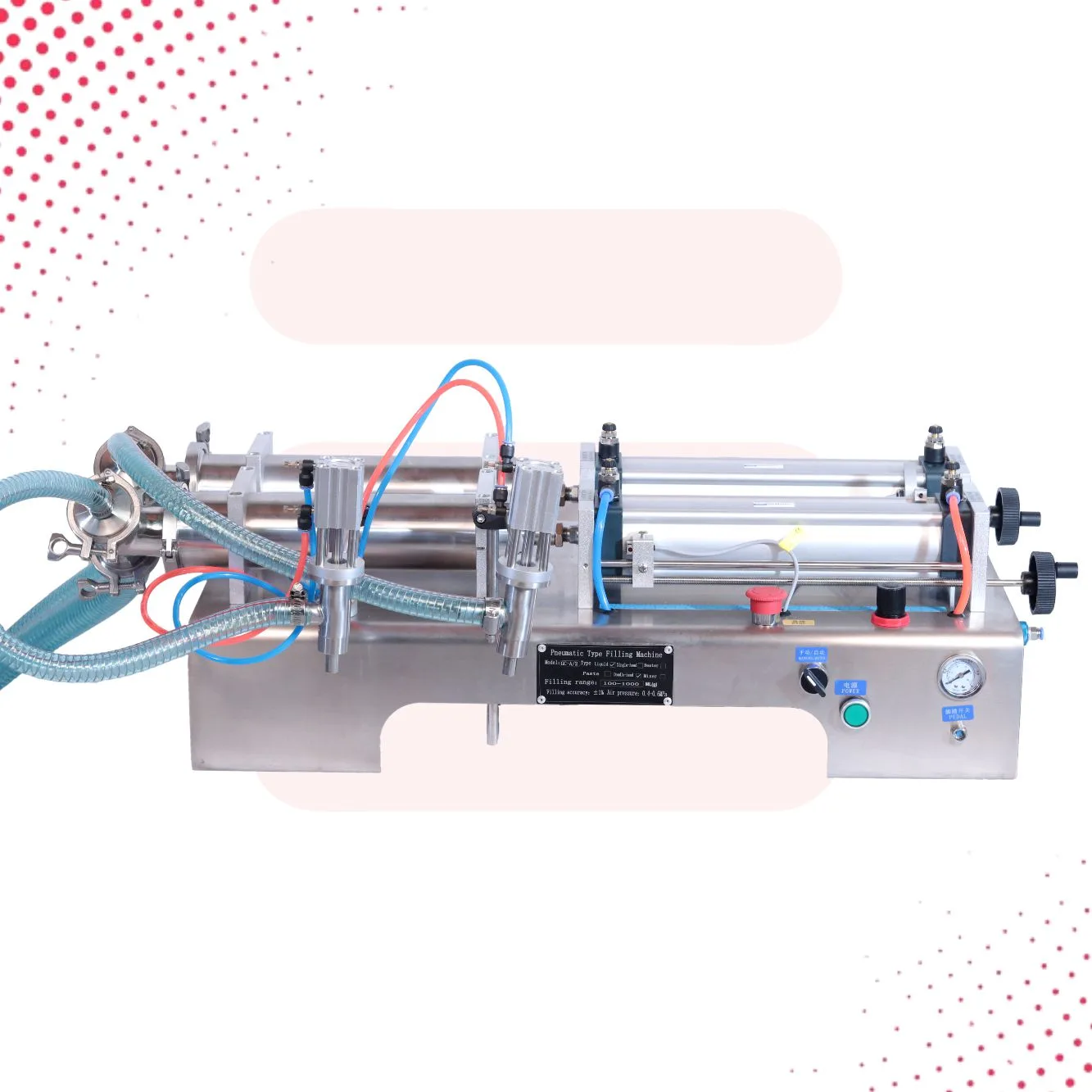

Pneumatic Liquid Filling Machine – 100ml to 1000ml

Semi-Automatic, Air-Powered, High-Accuracy Liquid Filler for Medium-Volume Production

Product Overview

The Pneumatic Liquid Filling Machine – 100ml to 1000ml is a highly efficient, semi-automatic, air-driven filling solution ideal for medium-sized containers ranging from 100ml up to 1 litre. Designed for industries that demand precision, hygiene, and scalability, this machine is perfectly suited for filling water, juice, sanitizers, edible oils, liquid chemicals, and more.

Built with SS304 food-grade stainless steel, it ensures long-lasting durability and contamination-free operation. The pneumatic design means it requires no electricity, operating solely on compressed air — a safe and cost-efficient solution for manufacturers operating in wet environments or hazardous zones.

This model is one of the most popular choices for SMEs, contract packaging units, and startup businesses that are scaling up from manual processes and need a machine that is accurate, affordable, easy to use, and flexible.

Key Features Pneumatic Liquid Filling Machine – 100ml to 1000ml :

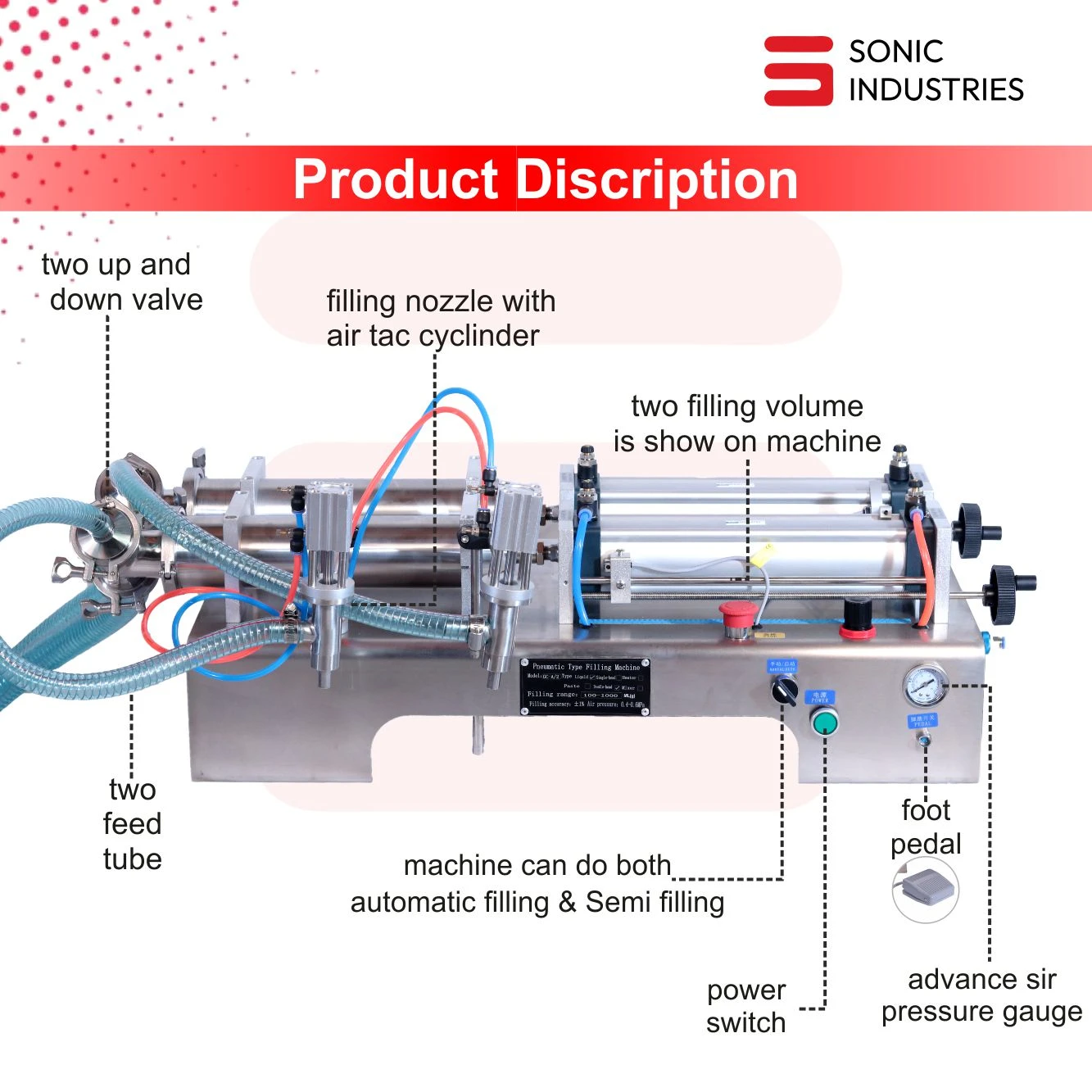

Adjustable Filling Range: 100ml to 1000ml

With a precise volume control system, this model easily adjusts to fill a wide variety of container sizes between 100ml and 1000ml, making it ideal for diverse product lines and packaging needs.

Pneumatic System – No Electricity Required

The machine works entirely on compressed air, making it suitable for explosion-prone, flammable, or wet areas such as juice processing units, pharma facilities, or chemical plants.

Precision Filling with ±1% Accuracy

Equipped with a piston-cylinder mechanism, this filler delivers reliable, repeatable accuracy that minimizes product waste and maintains consistent product presentation across every unit.

Anti-Drip Stainless Steel Nozzle

A specially designed anti-drip nozzle ensures clean fills without overflow or spillage. This minimizes waste and keeps the work environment clean and hygienic.

SS304 Food-Grade Construction

Every contact part of the machine is made with SS304 stainless steel, making it food-safe, rust-proof, and easy to sanitize. For more demanding applications, SS316 can be provided on request.

Semi-Automatic Control with Foot Pedal

Operators activate each fill cycle using a simple foot pedal, keeping both hands free to handle bottles. This ergonomic design reduces fatigue and speeds up production.

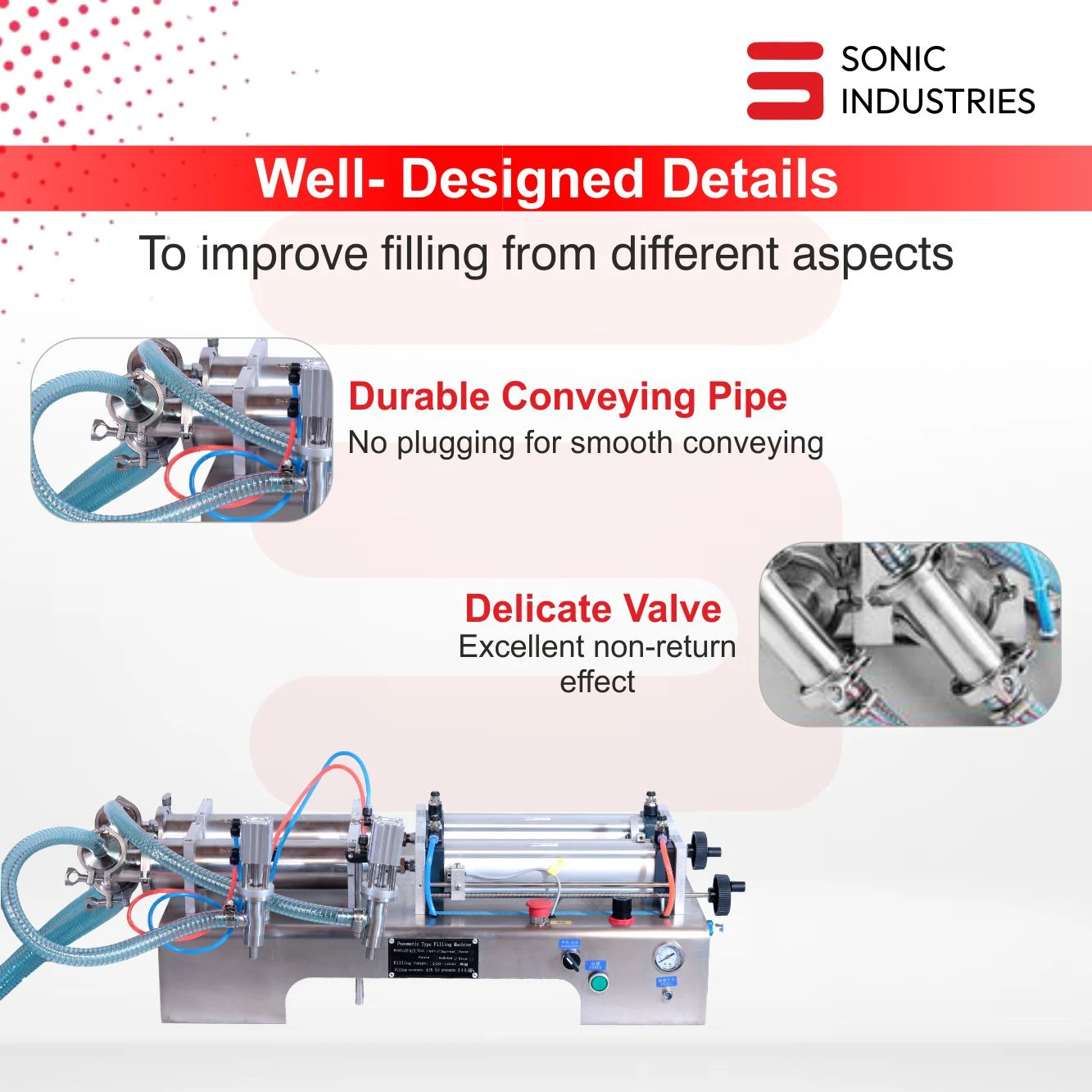

Easy to Clean & Maintain

Tool-free disassembly and simple design mean cleaning takes just a few minutes. This allows for quick product changes and compliance with GMP standards.

Technical Specifications

| Feature | Specification |

|---|---|

| Model | Pneumatic Liquid Filling Machine – 100ml to 1000ml |

| Filling Volume Range | 100ml to 1000ml (adjustable) |

| Accuracy | ±1% |

| Filling Speed | 8 – 18 bottles/min (depends on volume & operator) |

| Drive System | Pneumatic (Air Compressor) |

| Air Pressure Required | 0.4 – 0.6 MPa |

| Body Material | SS304 (SS316 optional) |

| Nozzle Type | Anti-Drip Stainless Steel |

| Hopper Capacity | 25L / 40L (customizable) |

| Control System | Foot Pedal / Manual Switch |

| Power Requirement | None (air only) |

| Dimensions (approx.) | 550mm × 500mm × 700mm |

| Weight | 30 – 45 Kg (depending on model) |

Compatible Liquids

This model handles a wide range of low-viscosity and semi-viscous liquids. It is not suitable for thick pastes or pulpy liquids. Here’s a breakdown by industry:

Beverages & Water

-

Packaged drinking water

-

Fresh fruit juices

-

Herbal drinks (amla, aloe vera, giloy)

-

Cold-pressed juices

-

Coconut water

Pharmaceuticals

-

Liquid syrups

-

Ayurvedic tonics

-

Nutraceuticals

-

Homeopathic medicines

-

Digestive blends

Cosmetics & Personal Care

-

Liquid soaps

-

Facial cleansers

-

Floral water (rose, sandalwood)

-

Body oil, hair oil

-

Skin lotions (low viscosity)

Chemical & Cleaning Products

-

Hand sanitizers

-

Liquid disinfectants

-

Floor cleaners

-

Fertilizer solutions

-

Detergent liquids

Ideal Applications

| Industry | Example Applications |

|---|---|

| Food & Beverage | Filling juice bottles, 1L water packs, herbal drinks |

| Pharma | Syrups, cough medicine, digestive formulations |

| Cosmetics | Facewash, toners, oils in 250ml or 500ml bottles |

| Chemical Industry | Sanitizers, liquid hand wash, toilet cleaners |

| Home Business | Boutique product packaging, health drinks |

| Contract Packers | Versatile filling for various client needs |

Benefits at a Glance

| Benefit | Impact |

|---|---|

| Electricity-Free | Ideal for power-scarce or wet environments |

| Food-Grade Safe | SS304 ensures hygienic and corrosion-free operation |

| High Accuracy | Maintains brand consistency and reduces product loss |

| Fast & Flexible | Handles 8–18 bottles per minute |

| Durable Construction | Rust-proof, industrial-grade build |

| Quick Cleaning | Tool-free disassembly, GMP-friendly |

| Customizable Output | Change volume on the fly without changing parts |

| No Dripping | Keeps workstation clean and saves product |

| Easy to Use | Requires minimal training for operators |

Optional Accessories

| Accessory | Purpose |

|---|---|

| SS316 Upgrade | Ideal for corrosive or pharma-grade products |

| Dual Nozzle | Fill two containers at once |

| Heated Hopper | Maintains fluidity of warm oils or syrups |

| Vacuum Anti-Foam Kit | For foaming liquids like handwash or sanitizer |

| Bottle Guide Stand | Ensures bottle alignment and reduces spillage |

| Trolley Mount | Mobility and adjustable working height |

Cleaning & Maintenance

Cleaning Instructions:

-

Disconnect the air supply

-

Open hopper clamp and remove it manually

-

Detach piston and nozzle using quick-release fittings

-

Rinse all parts with water or approved cleaning fluid

-

Reassemble and reconnect – ready for the next batch

Reviews

There are no reviews yet.